Measuring a Parking Lot for Asphalt Maintenance: Manual vs. AI Takeoff

Learn how to measure a parking lot for asphalt maintenance. Compare manual measurement to AI Takeoff, consider the pros and cons, and choose the correct method for your company

Posted by

Judson Burdon

on July 11

Proper measurements are the key to any profitable and successful asphalt maintenance project. If you are getting ready to stripe, crack fill, sealcoat, or patch a parking lot, it begins with knowing exactly what you are up against. You need accurate measurement first and foremost for the purpose of estimating your materials and labor, but also for generating confidence through professional, accurate proposals.

Getting it right the first time saves not only time but margin as well. Miscalculation of floor space means cash lost, overestimating means materials wasted and money wasted. Either way, profitability suffers.

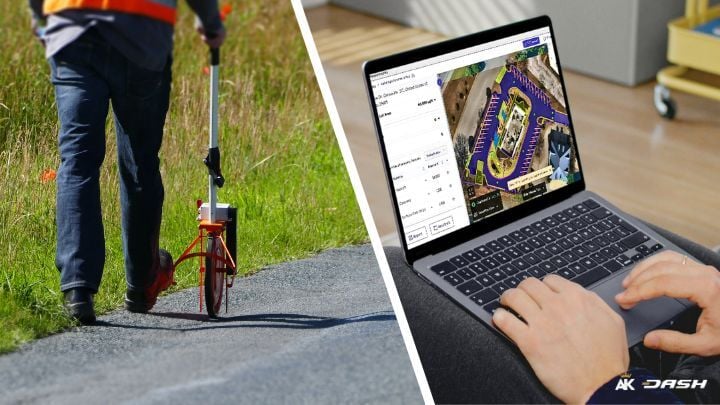

Here, we'll examine two popular methods contractors use in measuring parking lots today: the traditional manual approach and the AI-powered alternative that’s quickly taking center stage in the asphalt world.

Why Measuring a Parking Lot Accurately Matters

It's taken for granted too often as a daily task, but measurement impacts everything from pricing to production. Incorrect measurement can blow a job before the sealer ever goes on the pavement. Here's why measuring properly matters:

- Material accuracy: You'll exactly know how much gallons of asphalt sealer, pounds of crack filler, or gallons of line striping paint you’ll need.

- Labor planning: Helps you better predict how long the job will take and how many crew hours you'll need.

- Proposal confidence: Accurate quotes help you win more jobs without guesswork.

- Profit margin protection: Prevents overbuying materials or underquoting labor.

Manual Measurements: The Traditional Approach

Physical measurement is still the common method for most contractors. It does not usually involve anything more than a measuring wheel, tape measure, and pen and paper or phone notes to record square footage.

How It Works:

- Walk the length and width of each section of the lot using a measuring wheel.

- Break down irregular shapes into rectangles or triangles for easier math.

- Multiply length by width to calculate square footage.

- Add all areas together and subtract non-pavement features like curbs or landscaped islands.

✅ Pros of Manual Measurement:

- Simple and accessible: No apps or internet required.

- Eyes on the pavement: Spot oil stains, cracks, and puddles as you walk.

- Cost-effective: Basic tools only, no software fees.

❌ Cons:

- Takes time: Big lots can take hours to measure and record.

- Prone to errors: Fatigue or small mistakes can throw off your numbers.

- Weather-dependent: Hard to quantify precisely in rain or snow. Limits scalability: You can only measure a single site at a time, in person.

It's acceptable to measure manually for small projects and where you happen to be on site. It quickly reveals its limitations, though, where speed, quantity, or accuracy are a factor.

AI Takeoff: The Next Generation of Pavement Measurement

Artificial intelligence-based systems are a next generation of jobsite productivity. Technology like AI Takeoff, based on Attentive.ai technology, uses available aerial imagery and machine learning to easily and automatically tabulate parking lots, including asphalt surface area, striping, curbs, and ADA markings.

How It Works:

- Enter the job site location in the AI Takeoff platform e.g. AK DASH

- The tool gives you clear, high-resolution aerial images.

- It can detect pavement surfaces, markings, cracks, and curbs.

- You receive a digital measurement report with square footage, visuals, and breakdowns for each surface type.

- Export the results into your quoting or proposal software. In AK DASH’s case, the measurements from AI Takeoff are automatically integrated into your professional proposal

✅ Pros of Manual Measurement:

- Speed: It takes a little under 10 minutes for a full takeoff.

- Accuracy: Consistently scores 95–98% accuracy.

- Scalability: Enables contractors to measure dozens of sites per week, remotely.

- Proposal integration: Outputs are easily converted into client-ready documents.

- Remote-friendly: No need for site visits during the estimating phase.

❌ Cons:

- Learning curve and subscription cost: Requires investment in software, and time to learn how to efficiently use the software.

- Potential issues with covered lots: Parking lots with tree cover, carports, snow, or lots of parked vehicles may cause the AI to miss areas or require manual adjustments.

- No on-site context: AI often can’t detect surface damage, potholes, oil spots, or other on-the-ground issues that influence job planning or material usage.

AI Takeoff is steadily being taken up by contractors who are in need of faster, more repeatable measurements on many jobs. While not necessarily replacing manual methods in every case, it does offer a real-world solution for estimating productivity where quoting remotely or at scale is a necessity.

Side-by-Side Comparison

Feature |

Manual Measurement |

AI Takeoff |

|---|---|---|

Time Required |

1–2 hours per lot |

Under 10 minutes |

Accuracy |

Varies; subject to human error |

95–98% precision |

Cost |

Minimal (tools only) |

Software subscription |

Site Visit Required |

Yes |

No |

Scalability |

Limited |

High |

Output Format |

Handwritten notes or sketches |

Digital proposals with visuals |

Ideal Use Case |

Small/local jobs |

Commercial, remote, or high-volume bidding |

When to Use Each Method

Manual measurement still plays a role especially for:

- On-site inspections

- Verifying site conditions in person

- Small or residential lots

AI Takeoff is ideal when:

- You’re managing multiple bids per week

- You need to quote remotely

- You're scaling your business and want to streamline proposals

Many contractors use both methods; using AI Takeoff for quick estimates and quotes, then following up with manual checks for site preparation and final accuracy.

Final Thoughts

Accurate measurement is not paperwork. It is profit control. When you measure tight, you bid right, crews bring the right material, and jobs finish on time. Manual works for small, simple lots. But work is faster and more competitive now. AI Takeoff lets you turn takeoffs in minutes, quote more in a day, and protect your margins. If you bid often, handle big lots, or want to win more with less rework, upgrade your process. Measure smarter. Win more. Waste less.

.jpg?width=352&name=Untitled%20design(3).jpg)

.jpg?width=352&name=Blog%20Images%20(23).jpg)